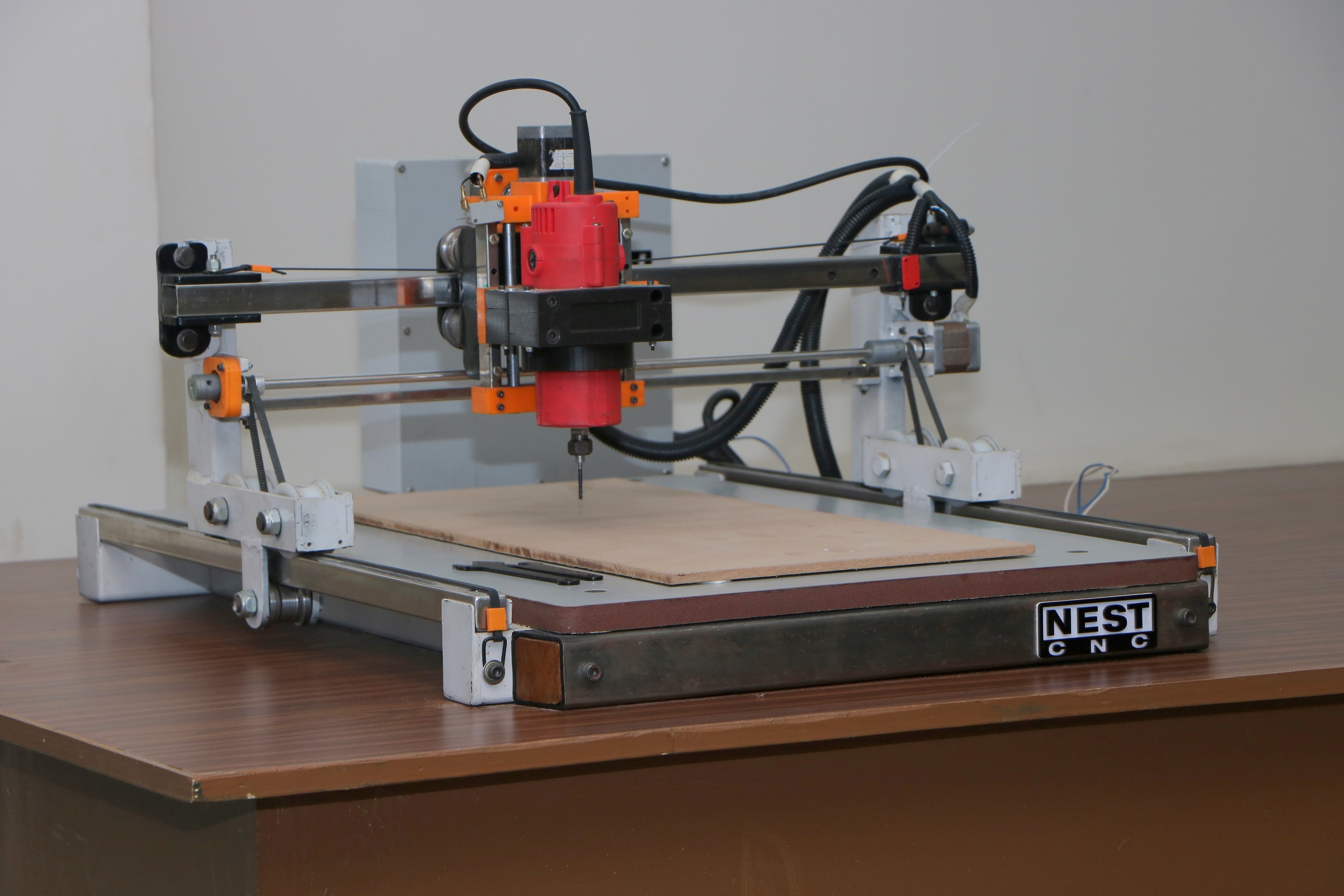

Ludhiana, July 18, 2019: CT University (CTU) under department of RICE – Research & Innovation Centre for Excellence has designed and developed a Precision Light application CNC (Computer Numeric Control) Milling Machine. This is yet another successful best out of waste project. The complete machine is manufactured using low cost and easily available raw material. It is designed and developed by students namely Gurjot Singh of Bachelors in Interior Designing, Gurpreet Kaur of B.Tech. (Mechanical Engineering) and Kiran Reddy of B.Tech. CSE (Artificial Intelligence).

The major usage of this machine is its infinite applications in engineering & technology, architecture, interior designing, dental & medical sciences. It can manufacture aluminium dyes for injection moulding as well.

Elaborating about the making of this product, Gurpreet Kaur,one of the students said, “The machine runs on AVR controller and powered by NEMA 17 Precision Stepper Motors using belt drive and lead screws. It has bed size of 700 x 400 x 100 MM. The overall cost of the machine is Rs.25000 only which can manufacture 2D & 3D complex shaped parts.”

Explaining the functioning of the project, Jaspreet Singh, R&D Engineer, said, “First the computer aided drawing of the part is designed in any CAD software like Auto CAD, Solid works, Fusion 360, Catia etc. then using the same CAD drawing G-codes are obtained through Computer Aided Machining software, like solid CAM and Fusion 360. These G Codes are fed to machine using GRBL controller. Following these G- codes, the machine cuts the fixed raw material in to the desired shape. The machine is rigid enough to cut aluminium, brass, copper, all types of plastic materials like Nylon, Polypropylene etc and all types of wood, plyboard and synthetic materials.”

“The machine is developed under start-up idea NEST which has also bagged third position in Start-up India Punjab Yatra, Business Idea Competition. The motto of this start-up is to provide low cost automation solution to small scale industry. Besides this, the students have also developed low cost precision FDM 3D Printers (NEST 3D) under same Start-up Idea.” said Dr Harsh Sadawarti, Vice Chancellor, CTU while congratulating the team and department.